|

|

Application solution of wear metal element analysis in lubricating oilpreface Oil is divided into three categories: lubricating oil, hydraulic oil, fuel oil.They play a very important role in equipment.For example, the lubricating oil is the “blood” of the engine, which plays multiple roles of lubrication, cooling, rust prevention, cleaning and sealing, etc., and the pollutants that contaminate the lubricating oil may block the oil filter and oil jet hole, making the oil pressure drop or even oil shortage.Oxidation or nitration of lubricating oil will accelerate the corrosion of friction pair surface.The change of lubricating oil viscosity will cause the decline of lubrication performance;These performance changes further cause a variety of engine failures, such as: engine vibration, abnormal rotation speed, oil consumption, noise, automatic engine shutdown, holding shaft, transmission shaft torsion and so on.Therefore, it is necessary to monitor the oil, monitor the condition of the equipment, predict the fault in advance, or diagnose the fault, so as to improve the reliability and maintenance level of the equipment. Different types of equipment failures occur, with wear and tear being the most common.Information indicates that 60-80% of equipment damage is caused by various forms of wear and tear.This is because two mechanical parts in contact with each other inevitably cause continuous loss and damage of surface materials when they move relative to each other.The oil in the mechanical system can carry rich information about the wear state of the mechanical friction pair, and through oil analysis technology, the equipment can be monitored and fault diagnosed.The oil analysis technology is to obtain the lubrication and wear state of the tribology system of the equipment by analyzing the performance change of the oil of the monitored equipment and the information of the wear particles it carries, so as to build a bridge between the condition monitoring and maintenance management of the equipment.

Sources of contaminants in lubricantsThe main sources of pollution are as follows: ① Different processing technology, different raw materials, the production of lubricating oil composition (such as gum, asphalt and other compounds content) is also different. ② The equipment for storing, transporting and adding oil materials is not clean, causing oil pollution. ③ Due to storage, transport, add oil careless, causing artificial pollution. ④ Metal shavings formed by friction between components of the lubricating oil system and gum and carbon deposits formed by oxidation of lubricating oil. ⑤ Poor compatibility between lubricating oil and mechanical parts causes component corrosion and produces corrosion products. ⑥ In the process of engine production and repair, pollutants remain in the lubricating oil system due to unclean cleaning.

Source of wear elements in general equipmentGenerally, there are three types of metal components in lubricating oil: wear element, pollution element and additive element. In the wear fault diagnosis, the change rule of wear element is mainly concerned, while in the analysis of oil quality, more attention is paid to the loss of external pollution element and additive.Specific categories are as follows:

The function and function of oil analysis and detection technologyOil analysis detection technology is based on the fact that because of the machine parts of the friction pair interaction, will produce tiny wear particles, the wear particles in lubricating system under the action of suspension in the oil, wear and tear down the particles contain important information of the wear status of the equipment, if can effectively analyze these types of wear particles, quantity, composition and its change rule, you can judge the mechanical parts wear state of friction pair.

Basic functions of oil analysis Oil analysis is through the equipment of oil system: lubrication system, hydraulic system, fuel system sampling analysis.To diagnose equipment and oil state of effective means.It is similar to how doctors diagnose a person’s health based on the results of tests on body fluids such as blood.Through oil analysis, the machine condition can be monitored in real time, providing accurate first-hand data for equipment operation, maintenance and management.

The following functions can be achieved by monitoring the equipment through oil analysis: ① Fault diagnosis of equipment: possible abnormal wear and failure can be predicted through various boundary values to avoid major accidents and reduce the failure rate;Monitor equipment status, improve operation safety, reduce unexpected downtime and improve equipment availability.This is the main function of oil analysis and monitoring. ② Correctly determine the life of the oil.The main factors affecting oil change include oil quality, sulfur content of fuel, working environment and oil consumption.There are two kinds of disadvantages of regular oil change: if the oil change is too late, the machine may be damaged, causing heavy losses;If the oil is changed too early, the oil that could have been used can be treated as waste oil, resulting in oil waste. ③ Study the wear rule and the wear mechanism, understand the material type, heat treatment method, machining accuracy and other aspects of the improvement effect, to provide a basis for the improvement of design. ④ Correctly specify equipment run-in specifications.Most of the previous run-in specifications used empirical data, lack of scientific basis.Using oil analysis technology in bench test can scientifically determine run-in specification, effectively shorten run-in period and save resources. ⑤ Determination of oil pollution: water and dust into the oil has great harm to equipment, through oil analysis and monitoring can detect the degree of oil pollution, so as to timely take countermeasures. ⑥ Understand the loss of additives in the oil, so as to timely supplement additives or replace new oil. ⑦ The correct equipment overhaul cycle, save maintenance costs, less spare parts inventory, greatly reduce operating costs, extend the service life of equipment.

Edx-300 special X fluorescence analyzer for lubricating oil wear metal

Edx-300 lube oil wear metal special X fluorescence analyzer is advanced technology level of high precision X fluorescence analyzer.It is mainly used for testing ships, vehicles, machinery, engines, propellers, bearing, gear box lubricating oil wear metal elements and the fast and exact analysis of additive elements, can analyze the Ca, Fe, Ti, V, Cr, Mn, Ni, Cu and zinc, Pb, Sn, Mo, Ag, Cd, Ba, S, P, such as the content of each element, 100 seconds to complete rapid determination of all elements, analysis of element content can range from PPM level to the pure elements and does not require complicated sample preparation process.It can also be used to detect sulfur content in crude oil, gasoline, diesel oil, residual oil, heavy oil and other petroleum products.

Edx-300 special X-ray fluorescence analyzer for lubricating oil wear metal meets the following domestic and foreign standards:Meet: ASTM d6595-00 (2011) error requirements for determination of wear metals and contaminants in lubricating and hydraulic oils. Determination of sulfur content in petroleum and petroleum products by energy dispersive X-ray fluorescence spectrometry D4294-023 ASTM method for determination of sulfur content in petroleum products (energy dispersive X-ray fluorescence spectrometry, national standard in the United States) 2003-11-01 D6445-99 ASTM gasoline determination of sulfur content (energy dispersive X-ray fluorescence spectrometry, national standard, USA) 2004-01-01 ISO 8754 determination of sulfur in petroleum products (energy dispersive X-ray fluorescence spectrometry, international standard) 2003-07-15 Determination of sulfur content in automotive fuel oil for petroleum products (energy dispersive X-ray fluorescence spectrometry, international standard) 2004-03-15

Instrument features:

Technical characteristics and parameters of the instrument1 Technical characteristics

D.Electronic circuit system with high signal-to-noise ratio.

2: Technical parameters

RH300 analyzer and other spectrometers Test the performance comparison of wear metal elements in lubricating oil

Examples of application

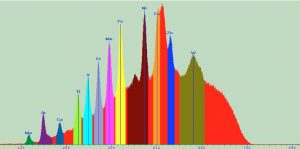

EDX-300 special X fluorescence analyzer for lubricating oil wear metal can be used to quickly detect the content of wear metal elements and additive elements in lubricating oil, such as Fe, Ca, Ni, Cu, Zn, Pb, Mo, Ti, V, Cr, Mn, Ag, Sn and other elements, the detection limit is less than 3ppm. The following figure is an example of the measurement spectrum of wear metal elements and additive elements in lubricating oil:

Examples of analysis results of wear metal in lubricating oil:

20 repeated test results:

Edx-300 lube oil wear metal special X fluorescence analyzer can also quickly analyze the sulfur content in various petroleum products, such as crude oil, gasoline, diesel, heavy oil, etc.

Comparison results of sulfur content in oil samples:

Multiple measurement repeatability

|