Refractory material refers to inorganic non-metallic material whose refractory degree is higher than 1580℃.Refractoriness refers to the Celsius temperature at which the conical specimen of refractories resists high temperature without softening melt-down under no load.The concomitant appearance of refractory and high temperature technology originated from the middle Bronze Age.In the eastern han dynasty of China, clay refractory materials were used as kiln logs and saggers to burn porcelain.

Classification of refractories

There are many kinds of refractories, which are usually divided into ordinary refractories (1580 ~ 1770℃), advanced refractories (1770 ~ 2000℃) and superior refractories (above 2000℃).According to the chemical characteristics of acid refractories, neutral refractories and alkaline refractories.In addition, there are refractories for special occasions.

Now for the definition of refractory, has not only depends on the refractory degree is more than 1580℃.At present, refractory materials generally refer to inorganic non-metallic materials used in lining of metallurgical, petrochemical, cement, ceramics and other production equipment.

Chemical composition of different refractories

Acid refractories with silica as the main component, commonly used brick and clay brick.Silica brick is a siliceous product containing more than 93% silica oxide. The raw materials used are silica stone and waste silica brick, etc. It has strong resistance to acid slag erosion, high softening temperature under load, and does not shrink or even expand slightly after repeated calcining.But it is easy to be eroded by alkaline slag and has poor thermal vibration resistance.Silicon brick is mainly used in coke oven, refractory furnace, acid steel furnace and other thermal equipment.Clay brick with refractory clay as the main raw material, containing 30% ~ 46% alumina, is a weak acid refractory material, good thermal vibration resistance, corrosion resistance to acid slag, widely used.

Neutral refractory is mainly composed of alumina, chromium oxide or carbon.Corundum products containing more than 95% alumina are high quality refractory materials with wide application.Chromium oxide brick has good corrosion resistance to steel slag, but poor thermal vibration resistance and low deformation temperature under high temperature load.Carbon refractory materials are carbon brick, graphite products and silicon carbide products, their thermal expansion coefficient is very low, high thermal conductivity, good thermal vibration resistance, high temperature strength, resistance to acid, alkali and salt erosion, not by metal and slag wetting, light.It is widely used as lining material of high temperature furnace, as well as lining of autoclave in petroleum and chemical industry.

Basic refractory is magnesium oxide, calcium oxide as the main components, commonly used is magnesia brick.Magnesite bricks containing more than 80% ~ 85% magnesium oxide have good resistance to basic slag and iron slag, and higher fire resistance than clay brick and silica brick.Mainly used in open hearth furnace, oxygen blowing converter, electric furnace, nonferrous metal smelting equipment and some high temperature equipment.

Refractory materials used in special occasions include high-temperature oxide materials, such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, refractory compound materials, such as carbide, nitride, boride, silicide and sulfide, etc.High temperature composite materials, mainly ceramic metal, high temperature inorganic coating and fiber reinforced ceramics.

The test elements for refractories are Na, Mg, Al, Si, K, Ca, Ti, Mn, Fe and Zr.Among them, Al, Si, Mg and Zr are the key elements.

Application solutions

The X-ray fluorescence analyzer has a good analysis effect on the raw materials of refractory industry and the elements composition of refractory products.The ELITE 600 X fluorescence analyzer can be used for testing incoming raw materials (silica, bauxite, magnesia) and refractory products in the refractory industry.

The ELITE 600 X fluorescence analyzer has the following unique advantages:

Meanwhile, all elements in the periodic table from sodium (Na) to uranium (U) are analyzed.

It can detect solid, liquid and powder without complicated sample preparation process.

Wide dynamic range of analysis and measurement, ranging from 10-6 to 100%;

Adopting the advanced super-sdd detector imported from the original package, it has the characteristics of high resolution and high counting rate, and the measurement time is short, and satisfactory results can be obtained within one minute.

Adopting the original import signal processing circuit, the processing speed is fast, the precision is high, the stability is reliable;

The X-ray tube is excited by positive and high pressure, and the excitation and test conditions are controlled and displayed digitally by computer software.

The detector does not need liquid nitrogen protection and can be easily applied in various areas.

Advanced automatic vacuum control and digital vacuum detection display, high degree of automation;

It has the function of sample spin, which can reduce the influence of sample surface roughness and streaks, and can be applied to various metal analysis industries.

The advanced instrument drift automatically corrects to ensure the long-term stability of the instrument;

High accuracy, good stability, low failure rate;

Adopt multi-layer shielding protection, radiation safety and reliability;

WINDOWS XP Chinese application software, unique and advanced analysis method, complete and powerful functions, simple operation, easy to use, analysis results stored in standard ACCESS database, easy to network with the batching system;

Main technical indicators:

Multifunctional sample setting device

The sample setting device of the ELITE 600 type X fluorescence analyzer has a sample chamber which can accommodate all kinds of samples being tested.

A. Sample type: solid, liquid, powder, coating;

B. Sample tray: measuring device that can rotate automatically;

C. Sample chamber environment: optional air, vacuum, helium.Automatic control by software, no manual operation.

X-ray tube excitation system

The excitation system adopts unique inverted right Angle optical structure design.Taking the 50KV positive and high voltage X-ray generator as the excitation source, the primary X-ray generated from the X-ray tube is directly excited after passing through the filter, and satisfactory analysis results can be obtained by selecting the excitation conditions.It consists of high voltage generator, X-ray generator and digital control display system.

A. High voltage generator: automatic digital control and display of voltage and current by software.

X-ray stability: 0.2%/8 hours;

Voltage range: 0V to 50kV continuously adjustable;

Current range: 0mA to 1mA continuously adjustable.

B. X-ray generator: adopt the bending-radiation type, low power, natural cooling, high life X-ray tube with a thickness of 125 microns of Be (beryllium) window, and select the target material according to the practical application needs.The selected target materials are Rh (rhodium target), Ag (silver target), Mo (molybdenum target), Ti (titanium target), etc.It has high excitation efficiency for light elements such as Na, Mg, Al, Si and S.

Advanced super-sdd X-ray detection system

SDD electrical refrigeration high resolution high count rate detector: Be (beryllium window) thickness of 7.5 micron.The X-ray of 55Fe 5.9keV had a resolution of 127eV at a count rate of 1000CPS.It has high sensitivity and resolution to Na, Mg, Al, Si and S.

Advanced imported energy spectrum instrumentation system

Original imported amplifier and other signal processors: adapt to high resolution, high count rate, with international advanced level;Automatically adjust the amplification factor, 2048 ADC output.

Computer analysis system

A. High-end brand-name computers

B. 17-inch high-resolution color LCD;

C.h. advanced laser printers.

The system software

A. Operation: WINDOS XP operating system software, powerful and easy to use;

B. Functions: display of energy spectrum, setting of analytical elements, energy scale, automatic control of high voltage and current of X-ray tube, automatic rotation control of samples, automatic vacuum control, communication with other computers, storage of standard database results;

C. Analysis methods: linear fitting, quadratic curve, strength correction, content correction, basic parameter method;

D. Automatic correction of instrument drift: ensure long-term stability of instrument analysis results.

Examples of application

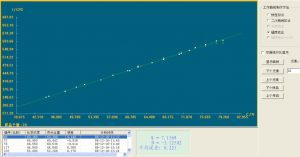

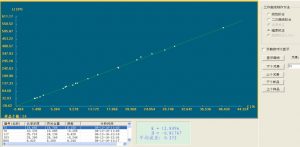

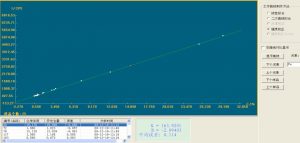

Analysis of bauxite

The analysis of bauxite samples is usually made by means of melting pieces, and the working curve is made.Measuring condition: 10KV/200uS 200S vacuum.

The working curve of each element is as follows:

Al’s working curve:

Si’s working curve:

Fe’s working curve:

The actual sample comparison results are as follows:

| Results of fluorescence analysis and chemical analysis of bauxite | |||||||

| Sample name | Analysis method | Al2O3 | SiO2 | Fe2O3 | TiO2 | CaO | K2O |

| XT-3 | chemical | 78.01 | 0.75 | 1.09 | 3.6 | 0.1 | 0.01 |

| X fluorescence | 77.88 | 0.89 | 1.26 | 3.59 | 0.08 | 0 | |

| error | 0.13 | -0.14 | -0.17 | 0.01 | 0.02 | 0.01 | |

| XT-5 | chemical | 75.15 | 4.12 | 1.32 | 3.1 | 0.36 | 0.03 |

| X fluorescence | 75.2 | 3.96 | 1.49 | 3.14 | 0.39 | 0.02 | |

| error | 0.05 | -0.16 | 0.17 | 0.04 | 0.03 | -0.01 | |

| XT-8 | chemical | 74.79 | 4.13 | 1.49 | 3.26 | 0.1 | 0.13 |

| X fluorescence | 74.94 | 4.16 | 1.66 | 3.15 | 0.07 | 0.11 | |

| error | 0.15 | 0.03 | 0.17 | -0.11 | -0.03 | -0.02 | |

| XT-10 | chemical | 72.05 | 8.37 | 0.66 | 3.09 | 0.12 | 0.2 |

| X fluorescence | 71.77 | 8.5 | 0.71 | 3.14 | 0.09 | 0.18 | |

| error | 0.28 | -0.13 | -0.05 | -0.05 | 0.03 | 0.02 | |

| XT-13 | chemical | 71.47 | 2.31 | 2.51 | 2.93 | 3.36 | 0.03 |

| X fluorescence | 71.47 | 2.51 | 2.46 | 3.05 | 3.24 | 0.05 | |

| error | 0 | 0.2 | -0.05 | 0.13 | -0.12 | 0.02 | |

| XT-15 | chemical | 71.2 | 8.92 | 0.85 | 2.85 | 0.26 | 0.15 |

| X fluorescence | 70.96 | 9.08 | 0.8 | 2.8 | 0.21 | 0.12 | |

| error | -0.24 | 0.16 | -0.05 | -0.05 | -0.05 | -0.03 | |

| XT-18 | chemical | 69.36 | 9.24 | 1.54 | 3.32 | 0.31 | 0.18 |

| X fluorescence | 69.5 | 9.54 | 1.63 | 3.32 | 0.37 | 0.18 | |

| error | 0.14 | 0.3 | 0.09 | 0 | 0.07 | 0.01 | |

| XT-20 | chemical | 70.63 | 2.6 | 8.03 | 2.9 | 0.05 | 0.06 |

| X fluorescence | 70.91 | 2.37 | 8.24 | 2.97 | 0.03 | 0.1 | |

| error | 0.28 | -0.23 | -0.21 | 0.08 | -0.02 | 0.04 | |

| XT-23 | chemical | 68.5 | 12.02 | 0.63 | 2.92 | 0.1 | 0.22 |

| X fluorescence | 68.41 | 11.52 | 0.72 | 2.85 | 0.11 | 0.23 | |

| error | -0.09 | -0.5 | 0.09 | -0.07 | 0.01 | 0.01 | |

Silicon refractory

Silica refractories are mainly composed of SiO2, and impurity elements include MgO, Al2O3, SO3, CaO, TiO2, Fe2O3 and other elements.The method is melting piece measurement, high precision, wide range of application, if the sample form is single, the content range is small, can also adopt direct powder pressing method of measurement.

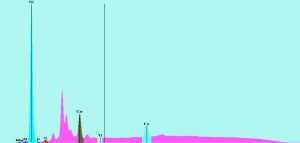

Measurement spectrum:

Analyze and compare test results

| Sample name | Methods | SiO2 | MgO | Al2O3 | SO3 | CaO | TiO2 | Fe2O3 |

| Silica sand – 1 | chemical | 99.16 | 0.34 | 0.30 | 0.032 | 0.005 | 0.038 | 0.114 |

| fluorescent | 99.25 | 0.03 | 0.28 | 0.030 | 0.004 | 0.032 | 0.104 | |

| error | 0.09 | -0.31 | -0.02 | -0.002 | -0.001 | -0.006 | -0.010 | |

| Silica brick – 3 | chemical | 95.41 | 0.39 | 0.60 | 0.037 | 2.500 | 0.049 | 0.639 |

| fluorescent | 95.23 | 0.42 | 0.65 | 0.043 | 2.610 | 0.043 | 0.621 | |

| error | -0.18 | 0.03 | 0.05 | 0.006 | 0.110 | -0.006 | -0.018 | |

| High quality silica sand -2 | chemical | 96.27 | 0.36 | 0.24 | 0.040 | 2.328 | 0.041 | 0.255 |

| fluorescent | 96.45 | 0.32 | 0.22 | 0.030 | 2.234 | 0.040 | 0.234 | |

| error | 0.18 | -0.04 | -0.02 | -0.010 | -0.094 | -0.001 | -0.021 | |

| Coke oven brick wall -4 | chemical | 95.13 | 0.39 | 0.61 | 0.036 | 2.553 | 0.058 | 0.670 |

| fluorescent | 95.31 | 0.34 | 0.65 | 0.032 | 2.435 | 0.068 | 0.610 | |

| error | 0.18 | -0.05 | 0.04 | -0.004 | -0.118 | 0.010 | -0.060 |

10 stability test results:

| 样品名称 | SiO2 | MgO | Al2O3 | SO3 | CaO | TiO2 | Fe2O3 |

| Coke oven brick wall -4 | 95.08 | 0.40 | 0.64 | 0.036 | 2.551 | 0.058 | 0.673 |

| Coke oven brick wall -4 | 95.11 | 0.39 | 0.64 | 0.037 | 2.550 | 0.058 | 0.670 |

| Coke oven brick wall -4 | 95.11 | 0.39 | 0.62 | 0.036 | 2.549 | 0.058 | 0.673 |

| Coke oven brick wall -4 | 95.05 | 0.38 | 0.65 | 0.037 | 2.545 | 0.058 | 0.671 |

| Coke oven brick wall -4 | 95.12 | 0.39 | 0.63 | 0.036 | 2.537 | 0.059 | 0.673 |

| Coke oven brick wall -4 | 95.10 | 0.39 | 0.62 | 0.037 | 2.542 | 0.058 | 0.674 |

| Coke oven brick wall -4 | 95.10 | 0.38 | 0.59 | 0.037 | 2.536 | 0.059 | 0.670 |

| Coke oven brick wall -4 | 95.09 | 0.39 | 0.64 | 0.037 | 2.555 | 0.058 | 0.668 |

| Coke oven brick wall -4 | 95.07 | 0.38 | 0.59 | 0.037 | 2.549 | 0.059 | 0.673 |

| Coke oven brick wall -4 | 95.13 | 0.39 | 0.61 | 0.036 | 2.553 | 0.058 | 0.670 |

| maximum | 95.13 | 0.40 | 0.65 | 0.037 | 2.555 | 0.059 | 0.674 |

| minimum value | 95.05 | 0.38 | 0.59 | 0.036 | 2.536 | 0.058 | 0.668 |

| average | 95.10 | 0.39 | 0.62 | 0.037 | 2.547 | 0.058 | 0.671 |

| error | 0.08 | 0.02 | 0.06 | 0.001 | 0.019 | 0.001 | 0.006 |

Magnesite samples

Magnesite sample is the main raw material of magnesite refractory material, the content of magnesium is more than 90%, and other impurity elements include Al2O3, SiO2, Fe2O3, CaO, etc.For the products with large content change, it is generally better to use the melting sheet method. For the products with small content change, direct pressing sheet can also meet the requirements of analysis accuracy.

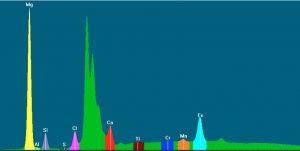

Measurement spectrum:

Comparison results of actual samples:

| sample name | methods | CaO2 | MgO | Al2O3 | Fe2O3 | SiO2 |

| 5 | study | 2.15 | 89.50 | 0.88 | 1.82 | 5.56 |

| Fluorspar light | 1.92 | 89.48 | 0.81 | 1.77 | 5.76 | |

| Poor miss | -0.23 | -0.02 | -0.07 | -0.05 | 0.20 | |

| 6 | study | 1.65 | 88.37 | 0.57 | 3.81 | 4.66 |

| Fluorspar light | 1.76 | 88.43 | 0.67 | 3.63 | 4.78 | |

| Poor miss | 0.11 | 0.06 | 0.10 | -0.18 | 0.12 | |

| 8 | study | 1.32 | 71.44 | 1.35 | 6.78 | 18.47 |

| Fluorspar light | 1.29 | 71.30 | 1.22 | 6.91 | 18.41 | |

| Poor miss | -0.03 | -0.14 | -0.13 | 0.13 | -0.06 | |

| 1 | study | 0.37 | 98.99 | 0.04 | 0.37 | 0.21 |

| Fluorspar light | 0.31 | 99.07 | 0.10 | 0.25 | 0.16 | |

| Poor miss | -0.06 | 0.08 | 0.06 | -0.12 | -0.05 | |

| 2 | study | 0.42 | 98.50 | 0.11 | 0.33 | 0.60 |

| Fluorspar light | 0.35 | 98.42 | 0.14 | -0.06 | 0.54 | |

| Poor miss | -0.07 | -0.08 | 0.03 | -0.39 | -0.06 | |

| 3 | study | 1.77 | 92.91 | 0.67 | 1.48 | 2.27 |

| Fluorspar light | 1.65 | 92.73 | 0.79 | 1.40 | 2.10 | |

| Poor miss | -0.12 | -0.18 | 0.12 | -0.08 | -0.17 | |

| 4 | study | 1.46 | 90.36 | 0.86 | 4.53 | 2.76 |

| Fluorspar light | 1.59 | 90.55 | 0.75 | 4.35 | 2.67 | |

| Poor miss | 0.13 | 0.19 | -0.11 | -0.18 | 0.11 |