|

Steel industry application solutionsX fluorescence analyzer in the steel industry rapidly and accurately analysis: the sinter, pellets, blast furnace slag, slag, iron ore, iron essence pink, pig iron, limestone, dolomite, ferro silicon, silicon, silicon manganese, ferromanganese alloy aluminum barium calcium and various kinds of steel samples, such as the world 600 type X fluorescence analyzer is especially suitable for the use of iron and steel industry, it analyzes elements can range from Na to U all the elements, fast analysis speed, only in 100 seconds to analyze the content of each element of the sample, the iron and steel industry is ideal for quick analysis instrument.

The ELITE 600 X fluorescence analyzer has the following unique advantages:

Main technical indicators:

The sample setting device of the ELITE 600 type X fluorescence analyzer has a sample chamber which can accommodate all kinds of samples being tested. A. Sample type: solid, liquid, powder, coating; B. Sample tray: measuring device that can rotate automatically; C. Sample chamber environment: optional air, vacuum, helium.Automatic control by software, no manual operation.

The excitation system adopts unique inverted right Angle optical structure design.Taking the 50KV positive and high voltage X-ray generator as the excitation source, the primary X-ray generated from the X-ray tube is directly excited after passing through the filter, and the best analysis results can be obtained by selecting the excitation conditions.It consists of high voltage generator, X-ray generator and digital control display system. High voltage generator: automatic digital control and display of voltage and current by software. X-ray stability: 0.2%/8 hours; Voltage range: 0V to 50kV continuously adjustable; Current range: 0mA to 1mA continuously adjustable. X-ray generator: adopt the bending-radiation type, low power, natural cooling, high life X-ray tube with a thickness of 125 microns of Be (beryllium) window, and select the target material according to the practical application needs.The selected target materials are Rh (rhodium target), Ag (silver target), Mo (molybdenum target), Ti (titanium target), etc.It has high excitation efficiency for light elements such as Na, Mg, Al, Si and S.

SDD electrical refrigeration high resolution high count rate detector: Be (beryllium window) thickness of 7.5 micron.The X-ray of 55Fe 5.9keV had a resolution of 127eV at a count rate of 1000CPS.It has high sensitivity and resolution to Na, Mg, Al, Si and S.

Original imported amplifier and other signal processors: adapt to high resolution, high count rate, with advanced technology level;Automatically adjust the amplification factor, 2048 ADC output.

A. High-end brand-name computers B. 17-inch high-resolution color LCD; C.h. advanced laser printers.

A. Operation: WINDOS XP operating system software, powerful and easy to use; B. Functions: display of energy spectrum, setting of analytical elements, energy scale, automatic control of high voltage and current of X-ray tube, automatic rotation control of samples, automatic vacuum control, communication with other computers, storage of standard database results; C. Analysis methods: linear fitting, quadratic curve, strength correction, content correction, basic parameter method; D. Automatic correction of instrument drift: ensure long-term stability of instrument analysis results. Examples of steel industry applications

Sinter samples are common analysis samples of iron works and sintering plants, among which TFe, SiO2, CaO, MgO, Al2O3, MnO, TiO2, P, S, K, V2O5 and other elements can be accurately analyzed by X fluorescence analyzer.Sinter samples are generally measured by direct tablet, and the fineness is required to be less than 180 mesh.

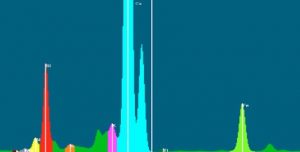

Measurement spectra of typical sinter samples:

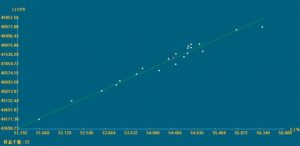

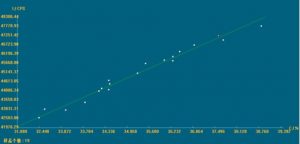

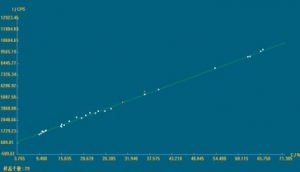

Working curve of sinter:

Analysis and comparison results of sinter production samples:

Pellet samples are common analysis samples of iron works and pelletizing plants, among which TFe, SiO2, CaO, MgO, Al2O3, MnO, TiO2, P, S, K, V2O5 and other elements can be accurately analyzed by X fluorescence analyzer.The sample is usually measured by direct tablet, and the fineness is less than 180 mesh. Measurement spectrum of pellets:

Analysis and comparison results of pellet production samples:

Blast furnace slag sample is a common analysis sample of iron works, converter slag is a common analysis sample of steel works, the X fluorescence analyzer can accurately analyze: SiO2, CaO, MgO, Al2O3, Tfe, MnO, TiO2, P, S, K, V2O5 and other elements.The sample is usually measured by direct tablet, and the fineness is less than 180 mesh. Measurement spectrum of blast furnace slag: The working curve of calcium in blast furnace slag

Analysis and comparison results of blast furnace slag production samples:

Analysis and comparison results of converter slag production samples:

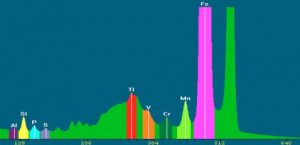

Pig iron samples are common samples for analysis in iron works, and the X fluorescence analyzer can accurately analyze such elements as Si, Mn, P, S, Ti, Cr, V and so on.The sample is required to be moulded, cut and polished with sand strip after pouring the sample, and sand paper is polished with 80 mesh. The surface of the sample is required to be free of pores. After polishing, it is required to be cleaned with alcohol cotton.The measurement requires the instrument to be set to spin state, while measuring the sample spin.When measuring, it is required to adopt double conditions. No filter is required to measure Si, Mn, P and S under the condition of 1#, and iron filter is required to measure Ti, V, Cr and other elements under the condition of 2#.

Analysis spectra of typical pig iron samples:

Analysis and comparison results of pig iron production samples:

Iron powder and iron ore samples are common samples for raw material analysis of steel works. The X fluorescence analyzer can accurately analyze TFe, SiO2, CaO, MgO, Al2O3, MnO, TiO2, P, S, K, V2O5 and other elements.Iron powder/iron ore using the standard method of melting, melting needs to add cobalt oxide as internal standard element, solvent using composite lithium tetraborate material.

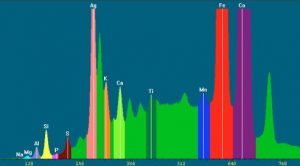

Analysis spectrum of typical iron powder samples: Analysis and comparison results of iron fine powder samples:

Working curve of Fe in iron ore:

The analysis results of actual iron ore samples on site are as follows:

The limestone samples are mainly analyzed for CaO, SiO2, Al2O3, Fe2O3 and other elements. The samples are pressed directly with a fineness less than 180 mesh. Measurement spectra of limestone samples:

Comparison results of limestone samples:

Dolomite samples are mainly analyzed for CaO, MgO, Al2O3, SiO2, Fe2O3 and other elements. Direct powder compression tablets can be used, and the fineness is required to be less than 180 mesh. Dolomite measurement spectrum:

Comparison results of typical samples are as follows:

|